Plastic Tensile Test Specimen Dimensions

Specimen a gauge length specimen b gauge length.

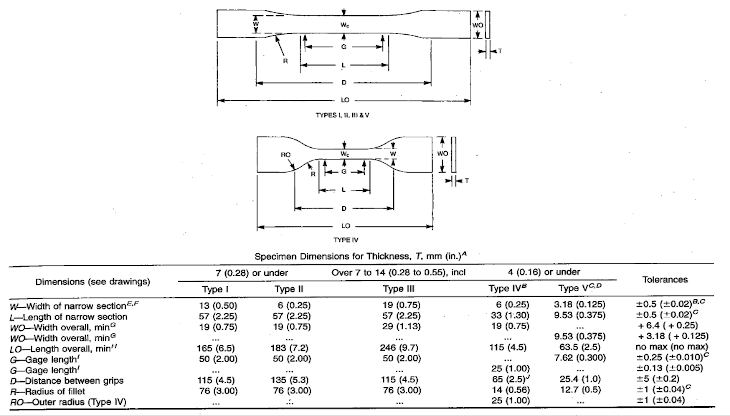

Plastic tensile test specimen dimensions. Tensile test purpose graph results specimen detail. The deformation of a rubber band is en. Specimen diameter 12 5 mm. D882 test method for tensile properties of thin plastic sheeting d883 terminology relating to plastics d1822 test method for tensile impact energy to break plastics and electrical insulating materials d3039 d3039m test method for tensile properties of poly mer matrix composite materials d4000 classification system for specifying plastic materi als.

It is very important to the tensile test to be considered is the standard dimensions and profiles are adhered to. 4 tensile testing second edition fig. While it provides similar results to astm d638 iso 527 2 is not considered technically equivalent due to differences in specimen size and test requirements while some large multinational manufacturers test to both astm d638 and iso 527 2 most of our customers demonstrate a. Flat dog bone specimens can also be die cut from a plastic sheet or machined from a block.

D882 test method for tensile properties of thin plastic sheeting. Versible deformation is called elastic deforma tion. When the tension test is started and specimen a or specimen b is pulled the strain is uniform along the gauge length up to the point at which the maximum force is reached and the onset of necking occurs. A universal testing machine tensile testing machine is needed to perform this test.

It is conducted on a universal testing machine also called a tensile testing machine at tensile rates ranging from 1 to 500 mm min until the specimen fails yields or breaks. D412 test methods for vulcanized rubber and thermoplastic elastomers tension. This test method uses standard dumbell or dogbone shaped specimens under 14mm of thickness. D883 terminology relating to plastics.

Astm d638 is performed by applying a tensile force to a sample specimen and measuring various properties of the specimen under stress. The stretch in each material is uniform up to this point. D618 practice for conditioning plastics for testing. D651 test method for test for tensile strength of molded electrical insulating materials.

The main principle of the tensile test is denotes the resistance of a material to a tensile load applied axially to a specimen. Specimens for astm d638 are dumbbell shaped with either a 25 mm or 50 mm gauge length. Iso 527 2 is an international standard for determining the tensile properties of reinforced and non reinforced plastics. An absolute accuracy of 10 μm for a 50 mm gauge length and relative accuracy within 0 5 are required by astm d638 for measuring the tensile modulus of elasticity.

Astm d638 is one of the most common plastic strength specifications and covers the tensile properties of unreinforced and reinforced plastics. 4 a load elongation curve from a tensile test and b corresponding engineering stress strain curve. A dog bone or dumbbell specimen is used to tensile test plastic materials per astm d638. The plastic dog bones are typically molded in a die to produce test specimens depending on the specific requirements of the applicable tensile testing standards.

A 50 mm gauge length is recommended.