Plate Rolling Machine Design Calculations Pdf

Whereby the bent plate can be removed from the machine.

Plate rolling machine design calculations pdf. 1 3 objectives of the work. Although there are many. Calculations of components 3 1 design of spur gear material en8 hardened and tempered s ut 550n mm 2. To make in minimum cost.

To reduce the time for operation. The following are the objectives of the work. Rolling machine for small scale manufacturers ijert vol 1 may2013. To make a bending machine to bend metal sheets up to 8 mm.

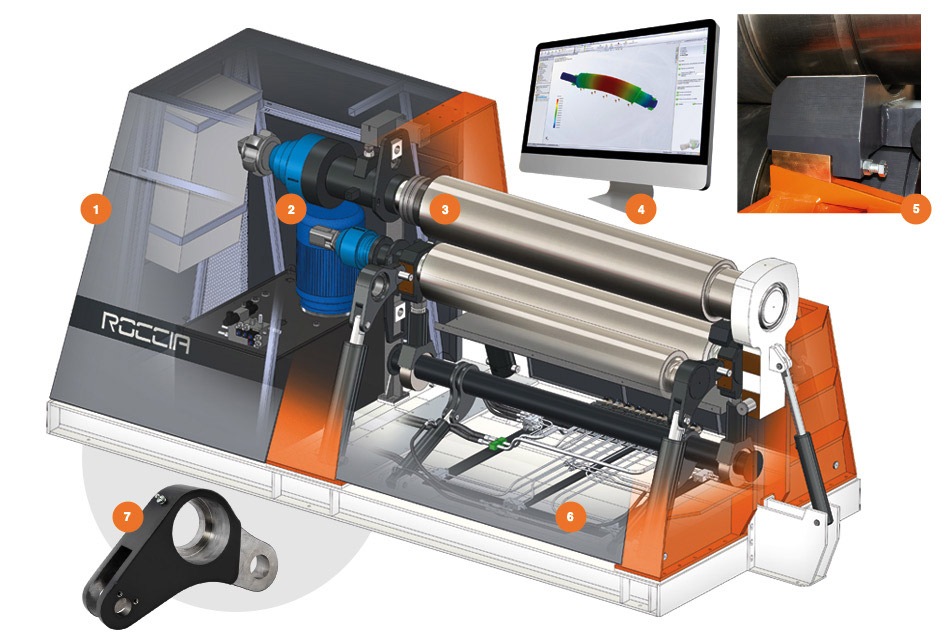

Mechanics and machine design equations and calculators design of load carrying shaft with one pulley supported by two bearings flywheel effect or polar moment of inertia lifting boom davits application and design equations large and small diameter lifting pulley drums two lifting lifting pulley s mechanical advantage multiple pulley s lifting mechanical advantage mechanical. Design development of three roller sheet bending machine mahesh gadekar1 mr. Design and fabrication of sheet rolling machine a project report. To make on simple working principle.

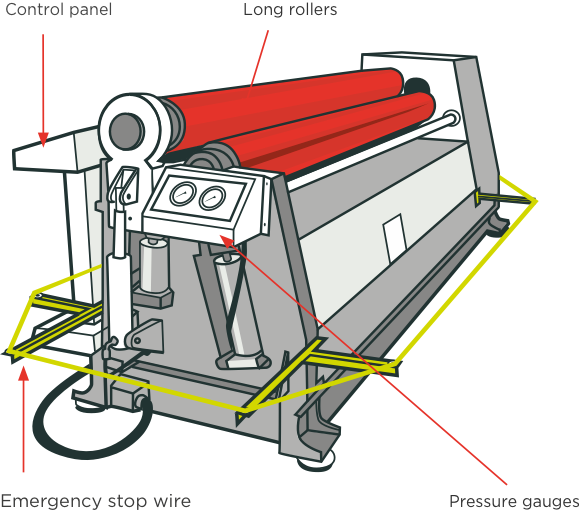

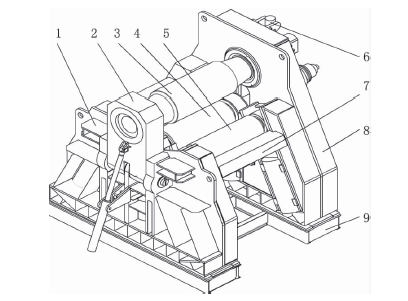

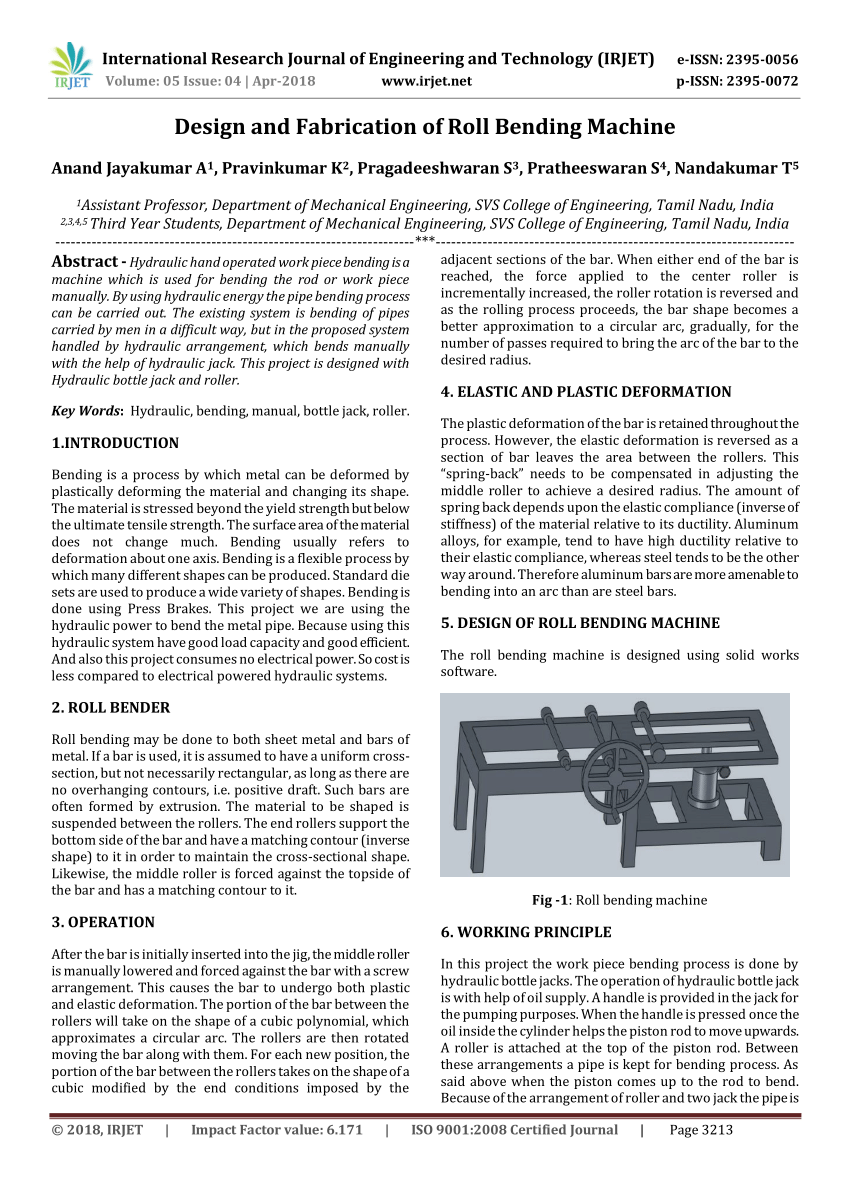

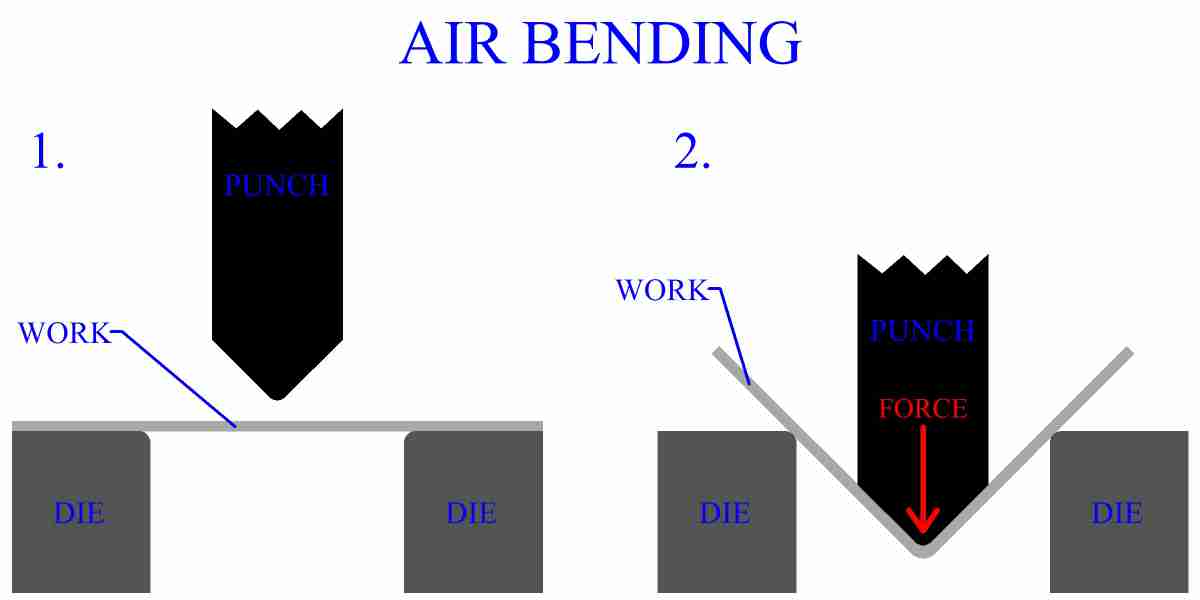

Amol 2 student1 asst prof2 dept. Sheet metalworking terminology punchanddie tooling perform cutting bending and drawing stamping press machine tool that performs most sheet metal plate bending rolls and slip roll machines for rolling sheet metal and plate into semicircles cylinder shapes cones. The present innovation relates to the plate bending machine which operates with rollers. The research aims at making it possible to do the operations on a single machine.

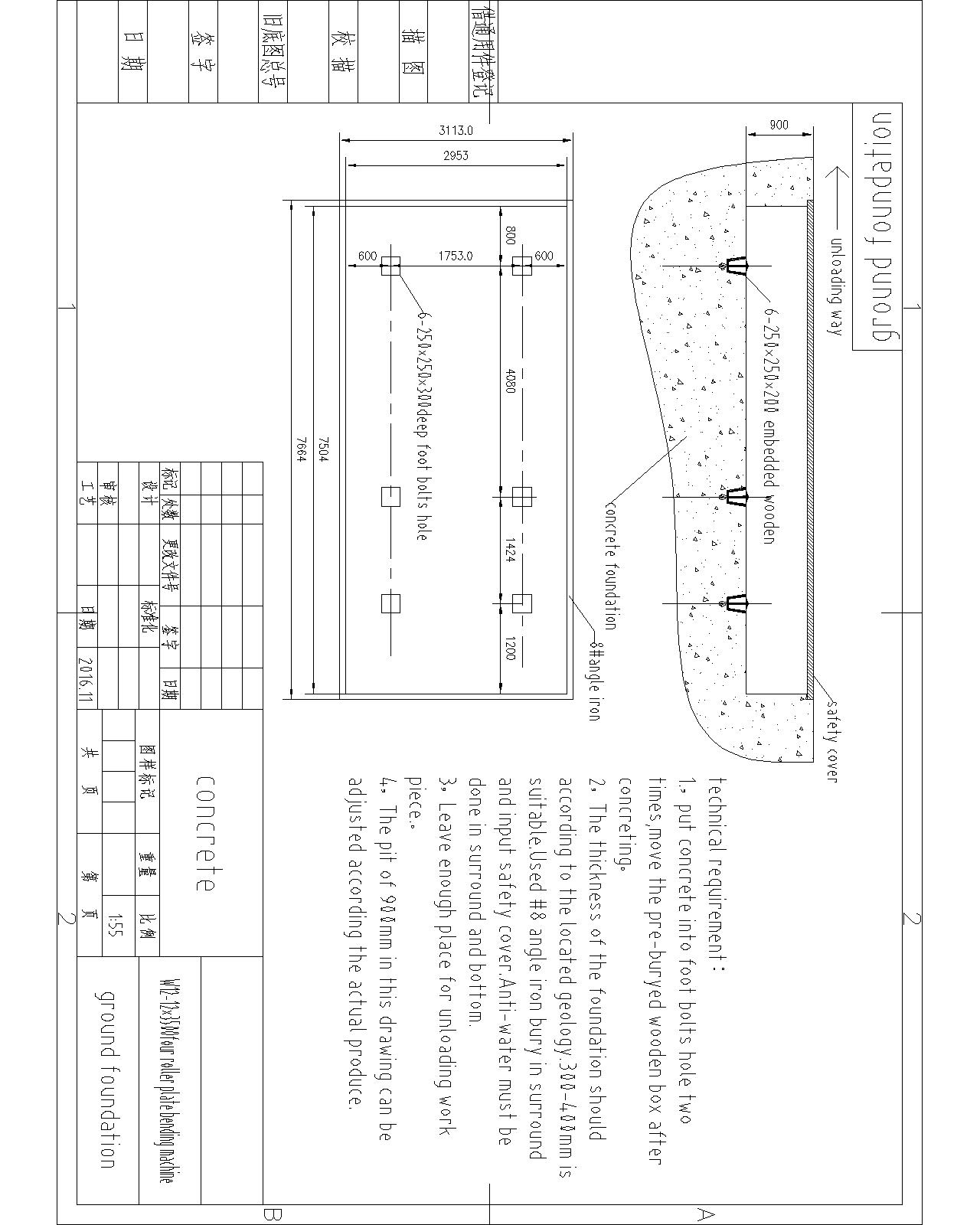

2 12 the core and cavity plate 14 2 13 injection molding machine 15 2 14 injection molding machine 17. Make free hand sketches of various ways the machine might be constructed at the same time making any preliminary calculations which might be required to. Plate rolling machine design pdf. A plate rolling machine is a machine that will roll different kinds of metal sheet into a round or conical shape and a rod bending machine will roll or bend different kinds of metal sheet into right angles or circular shapes.

2 2 1 two plate mould 4 2 2 2 three plate mould 5 2 3 basic mould contraction 6. Before starting work on the design of any machine get thoroughly familiar with what the machine is intended to accomplish and what special requirements or limitations must be considered.