Plating Tank Heaters

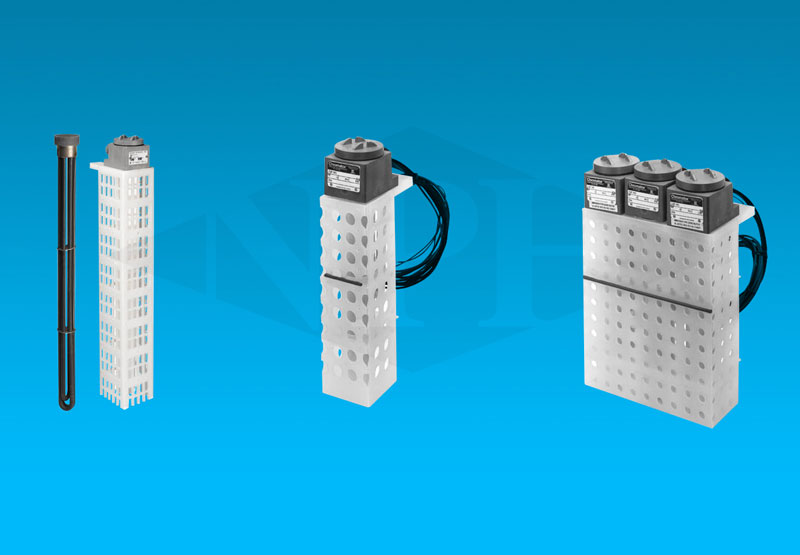

Replaces quartz alumina or graphite heaters.

Plating tank heaters. Quartz or ptfe more commonly known as teflon coated immersion heaters are used in acidic solution tanks. As well as careful material selection element configurations and wattages to meet specific operational needs. These heaters are equipped with a vapor tight terminal enclosure and a 3 foot long vinyl covered flexible conduit containing the two power leads and a ground wire. The ideal heating system heats the solution quickly usually in 2 3 hours.

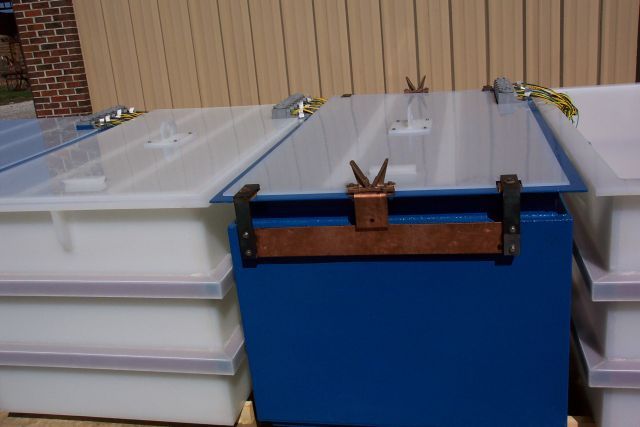

Provided with all necessary equipment for your plating needs. Best to heat the tank quickly in about in 2 3 hours. Acid tank heaters. The type 316 stainless steel is passivated to provide additional corrosion resistance.

Recently we are planning to purchase cooling systems for chrome plating tanks. Wattco custom manufactures electric heaters for plating tanks. We need information about cooling equipment. The pth series models are heavy duty general purpose heaters for heating plating tanks rinse tanks and other aqueous solutions.

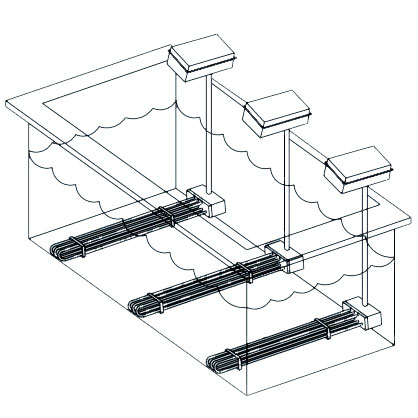

Down draft gas burners in a immersion tube system are used to heat large tanks of 2000 gallons double boiler tank with ptfe teflon liner or electric over the side and l shaped or bottom immersion heaters. We also fabricate single double and triple rinse tanks drag outs acid and sump tanks. Heating and cooling of chrome plating tanks. Compatible with most plating tank solutions inert to acids anodizing and pickling solutions up to 212 degrees fahrenheit 100 degrees celsius temperature.

Plating tank heater quotes. Acid tank heaters are used in nickel and chrome plating tanks made of either quartz or ptfe. Anode baskets bags hooks spin dryer dipping baskets filter cartridges horizontal discs bags barrel plating equipment chemicals tanks tank liners tank magnets mixers agitators dispensers accessories flexkraft switch mode rectifiers surplus inventory. Most popular heating methods for electroless nickel plating tanks are.

Buchholz smith features single stand alone polypropylene plating tanks in any size for rack and barrel. Immersion heaters for polypro tanks. There are several different ways to heat a phosphate plating tank. Auto catalytic nickel plating is referred to as electroless nickel plating en plating using a heated solution.

Quartz heaters can resist baths ph 0 to 9 exception is hyrdrofluoric acids and caustics we sell ptfe immersion heaters for less than 9 concentration hydrofluoric acid. We offer electrically heated designs for polypro tanks stainless steel tanks and double boiler tanks. A discussion started in 2000 but continuing through 2019. We have gas fired or electrically heated designs for polypro tanks stainless steel tanks and double boiler tanks.